The methods of joining rod sections together are many and each have strengths and weaknesses. From spliced joints to many the styles and materials of ferrules, the options effect both the action of the rod as well as the aesthetics.

Ferrule styles

Super swiss style allows the diameter of both the female and male sections to be the same where they fit the ferrules. The thinking is that the Super swiss style provides a stronger joint to support the forces transferred through the slide in use. The disadvantage of Super swiss style is that they are thicker than the bamboo so cause a swollen look on the rod as well as added stiffness to some degree and do cause a noticeable amount of air resistance compared to Step Down ferules and they are slightly heavier adding to the swing weight of the rod.

The Step Down ferrule design sees the female inside diameter the same as the bamboo shaft and the male reduced to fit the female. The advantage is there is no swelling at the mid point of the rod because the ferrule is closer to the dimensions of the rod and is lighter than a Super swiss style ferrule. The stepdown design is noticeably slimmer and this also enhances the rod action it being less stiff than a Regular ferrule.

Truncated ferrules are ferrules that are reduced to ~ 75% of the length of the standard female and male.

Truncated ferrules are used to save weight and help achieve the desired rod action. Typically these are used on the tip section of a three or four section rod. Both stepdown and Super swiss style ferrules are also available as Truncated.

Micro ferrules are ferrules that are reduced to ~ 50% of the length of the standard female and male. These specialty ferrules provide the ultimate light weight metal ferrules with minimal affect on rod bending in use. These are only recommended for the lightest weight rods.

Ferrule materials

Nickel Silver is the traditional material for metal ferrules. Not prone to galling and provides more than adequate strength needed for ferrules.

Nickel Aluminum Bronze alloy developed for the aerospace, mining and naval industries is a very strong, highly corrosion resistant material that has excellent wear and self mating properties. This material is lighter and stronger than nickel silver. This makes Nickel Aluminum a great material choice where strength coupled with reduced weight is needed. The material does take on a bronze coloration over time. They can be blued negating the coloration.

Aluminum ferrules are the lightest ferrule material. The downsides are a propensity to sticking or galling. Also the metal does not polish up as well as NS. If weight is the primary factor then Aluminum at less than half the weight of NS is worth considering.

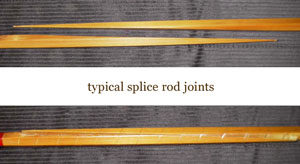

Spliced joints are used primarily on spey rods. It makes the rod act as one piece transferring the stress smoothly to a stronger portion of the rod. The splice joint is bound with tape when assembling the rod and removed when disassembling the sections.